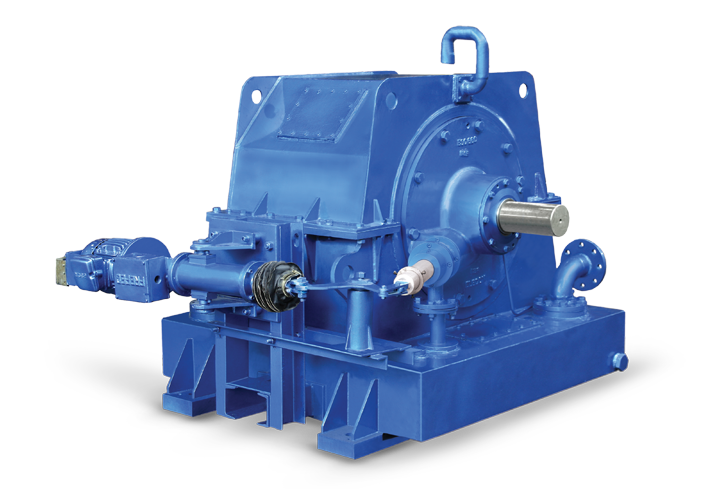

Elecon Scoop Coupling

There are mainly two parts called Impeller and Runner, both have a large number of straight radial vanes. The motor drives the impeller. The runner is connected to the driven machine. In running condition, the working circuit of the scoop coupling is filled with the oil and the impeller acts as a centrifugal pump, creating oil flow radially outward, which crosses the gap to the runner, which acts as a turbine. The oil flow given up power as it return to the impeller again and thus the cycle is repeated. As the fluid flow from impeller to runner is an essential feature of this power transmission, there is slip between these two parts. Due to the slip, there is heating of oil, which requires external cooling system for oil. The oil pump continuously supplies oil to the coupling. The output speed of coupling can be changed by varying the slip, which depends upon the oil quantity maintained in the working circuit by changing the position of the scoop tube. If the scoop tube is moved into the rotating ring of oil, it progressively removes the oil from the chamber and working circuit and discharges it into the sump. Inversely, moving the scoop tube from the oil ring allows retaining more oil in the working circuit.

- Size: ESC-480 ---- ESC-1030

- Power: 20 ----- 2320 kW